As you know, I like to build models and 3D print them. I’ve had Rostock Max v3 printer for a couple of years now that I’ve been very happy with. With it’s ~11″ diameter bed and ~16″ maximum height, it has allowed me to do some really large prints like my 12″ Assault Scout and my dice towers. I’ve also used it to print parts to repair things around my house or other useful gadgets.

Types of Printing

As a fused deposition modeling (FDM) printer with a 0.5mm nozzle, one thing the Rostock doesn’t do is super fine detail on small scales. It’s good enough for the spaceship models I’ve been making, especially since I designed the ships with the capabilities of the printer in mind. However, some of the models that I made to recreate old metal miniatures are right on the edge of what the printer could do. And while they print fine, they could be better. It definitely doesn’t do well enough to print small 28mm scale miniature figures with all their detail.

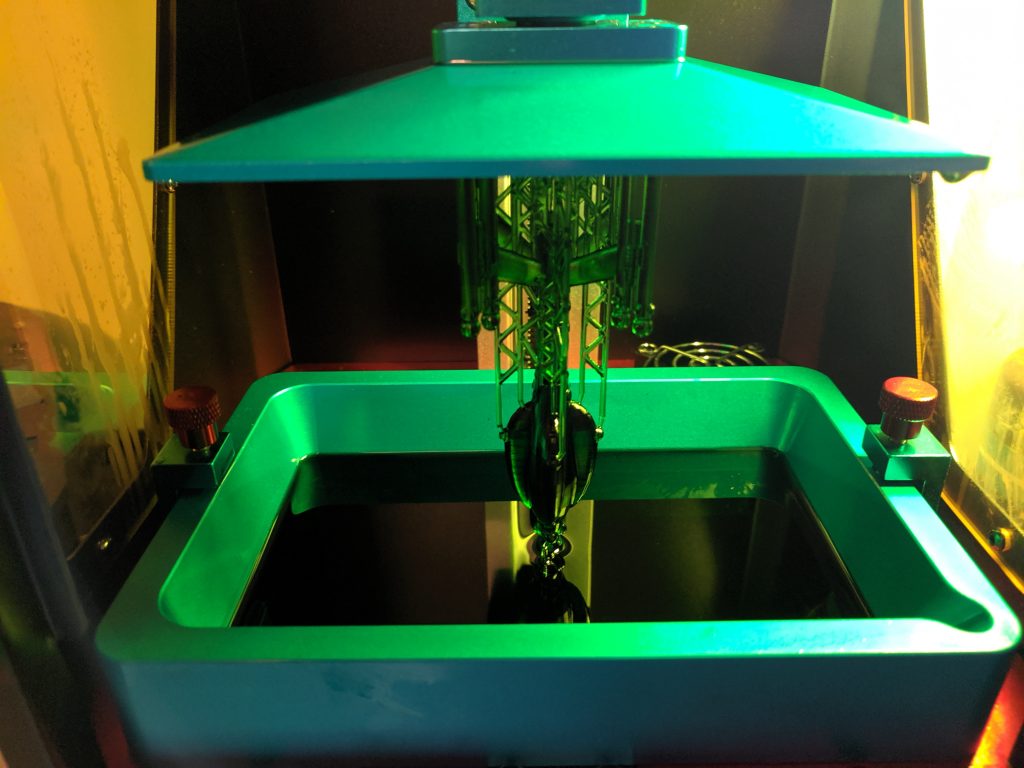

So earlier this month I purchased a new printer to compliment the Rostock on the small scale: an Anycubic Photon. Unlike the FDM printer that uses filament to lay down layers of material to create the print, the Photon is a Stereolithography (SLA) printer. It uses a UV sensitive resin and shines a UV light on the resin, hardening it for each layer. Early (and more high end) SLA printers use lasers as the light source. The Photon uses a UV LED screen. So instead of having to move back and forth across the print area to put down filament, it exposes the entire print surface at once.

Resolution & Build Volume

My Rostock has a cylindrical build volume 280mm in diameter and 405mm tall. Vertically, it can theoretically do 0.06mm layers but in practice, anything less than 0.1 mm doesn’t work but at that thickness and higher it works just fine. So I would use 0.1mm for high detail prints and 0.2mm as the default for large prints. That’s the vertical direction, in the horizontal direction, the positional accuracy was on the order of 0.05 mm but with the 0.5mm nozzle, you get actual resolution more on the order of 0.2mm.

The Photon is much much smaller. The picture at right shows them side by side. The print volume on the Photon is rectangular, 121mm wide, 68mm deep, and 150mm tall. However, that 121×68 mm print bed is imaged by a screen that is 2560×1440 pixels in size. That works out to a resolution in the x and y directions of 0.0475mm, 4 times better than what I can achieve with the Rostock. In the vertical direction, the default layer height is 0.05mm and it can go as low as 0.02mm, although I haven’t tried that yet as the 0.05mm height is amazing. It can go as thick as 0.1mm. So the default vertical resolution is already 2 times better than the best the Rostock can do and it has the capability to go even finer. The cost is print time and build volume.

Some Prints

Before I talk about the printing process, it’s time for some pictures. I’m still testing things out, but the default settings produce some amazing prints.

The images below shows a pair of miniatures that I printed for my daughter’s friends. I had tried printing them on the Rostock and it just couldn’t do it. The discoloration on the print of the sorceress is due to an alternate curing method I was trying out (more on that later). You can see the folds in their clothes and hair, and details in their armor.

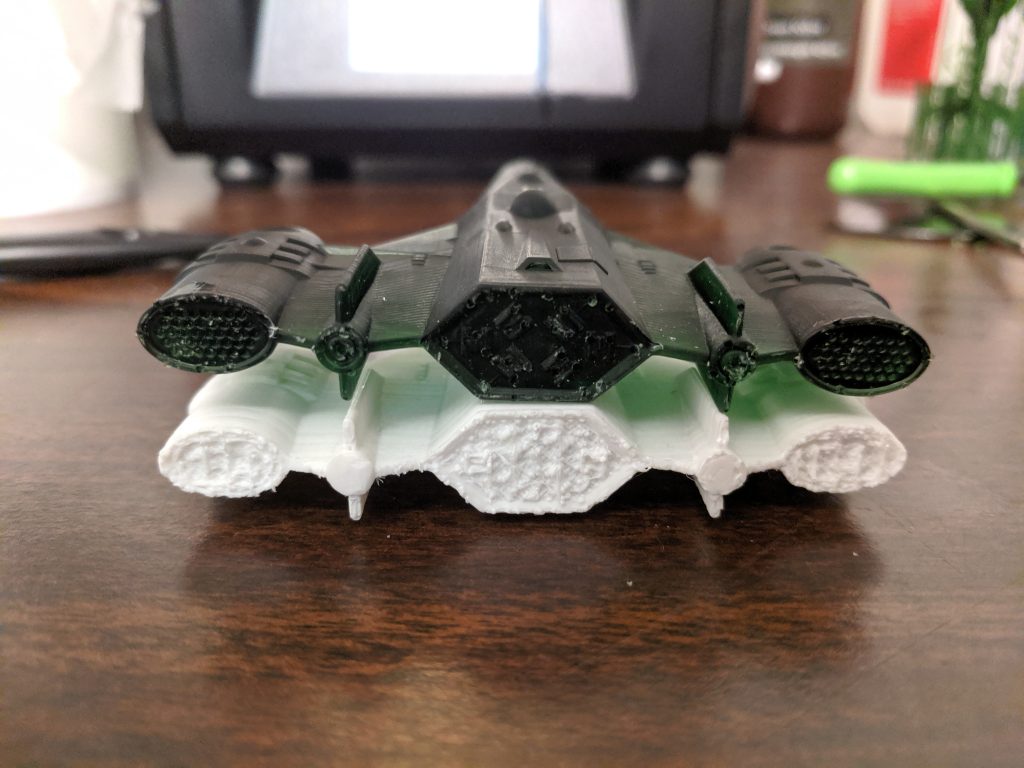

The printer came with the green resin and that’s what I’ve been using. I’ve ordered some white, black, and grey resin but I’m waiting for it to arrive. Next up we have the pirate corvette. The silver one was printed on my Rostock and the green of course is the new Photon. You can see the difference immediately. The resin print is much smoother and doesn’t have the banding from the print layers that the FDM print has. That wasn’t actually the best print from my Rostock so it’s not a completely fair comparison but the new one is just that much better.

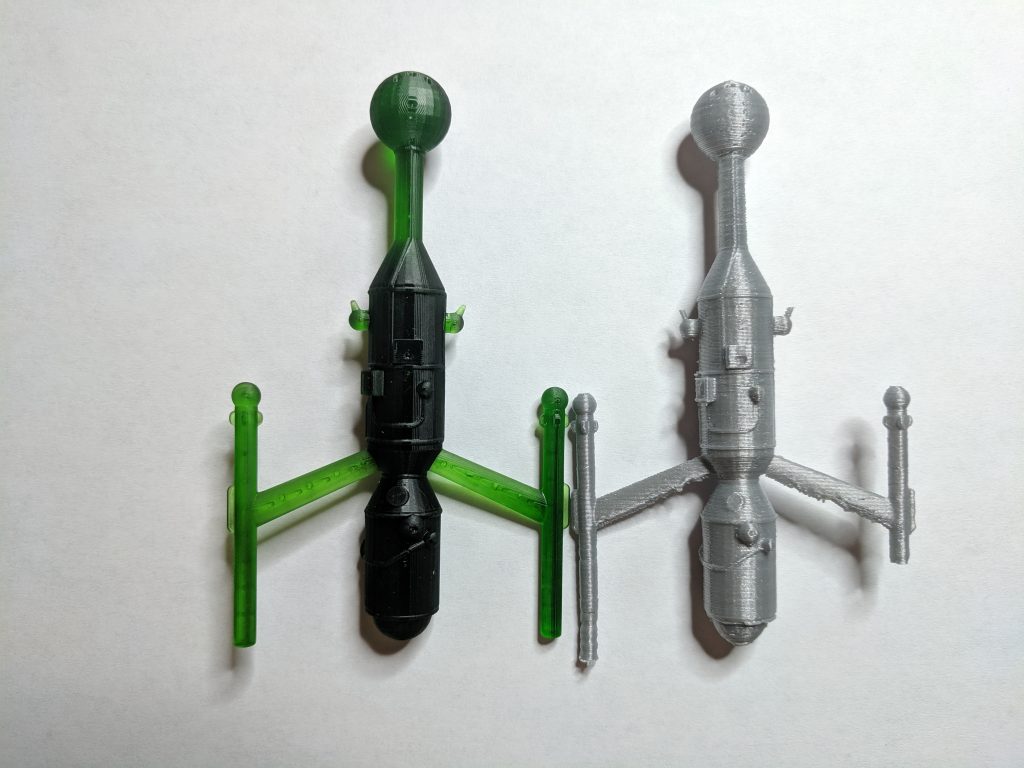

This image shows my sathar destroyer and hull 6 freighter models printed with both printers. The main thing visible in this set of prints is that the physical dimensions of the prints are more accurate with the resin printer. For example the bulb at the head of the destroyer is a bit distorted in the FDM print. Another thing that’s not as easily visible in this picture (as I wasn’t thinking about it when I took the picture) is that there are some fine details of bay doors and airlocks on both models that are just barely there on the FDM print but easily visible on the resin print. The other thing that stands out is that the barrels on my laser batteries (on the freighter) show up just fine in the resin print.

This next print I did to test out the resolution. The two prints are the exact same model file. The white one was printed with 0.1mm resolution on the Rostock and is 4″ tall. That was the scale (1/500th) that I designed the model to print at. I’ve also printed it at 1/333th, 6mm, and 10mm scales (6″, ~8″, and ~12″ tall. If you want one, you can order them here). The small one was printed just 1″ tall (1/2000th scale). It’s hard to see it in the picture, but every detail you can see on the large model, is also on the little one.

In addition, because of the very high resolution of the resin printer, details on the bottom of the model (back of the engines and fuselage), which didn’t print very well on the FDM version, are hinted at on that 1″ print but completely visible on a full-sized 4″ print as seen in the image below.

Next we have a comparison of the sathar light cruiser model. The FDM printed one has suffered some battle damage from my little boys playing with it. This is their favorite model of the bunch for some reason. Now the FDM version is pretty good but suffers on the underside of the engine struts. Otherwise it looks pretty good. But what blew me away when I got this print finished was the surface detail on the resin print. If you look closely at the head of the ship and the upper fuselage, you can see that the surface is faceted by a bunch of flat surfaces. That is the actual shape of the model file, not a printing artifact. It is washed out by the lower resolution of the FDM printer but the resolution is so high on the resin printer that the fact that I only used 50 faces to model circles is evident in the print. Those are the individual hull plates used to build the ship. At least that’s the story I’m sticking to.

The image below is the tallest print I’ve done, the sathar heavy cruiser. This one is about at the limit of the printer standing 142mm tall. In this case, I haven’t removed the support material from either of the prints so you can see what that looks like before it is all cleaned off. Not much more to add with these ones.

Finally, we have a collection of the smaller ships. These are all models, like the two above, that duplicate the original metal miniatures as exactly as I could (which turned out to be pretty close). We have the UPF and sathar frigates, the sathar cutter (which is the silhouette used on the UPF minelayer chit, but called the sathar cutter on the blister pack), and the pirate and UPF assault scout.

The Printing Process

The Photon’s SLA printing process comes with a different set of experiences, constraints, and challenges as compared with a FDM printer. The most obvious one is that everything is printed upside down.

Build Plate Adhesion

The layer being printed is at the bottom of the pool of resin. The UV light shines there to cure the resin, then the build plate slowly lifts to separate it from the teflon panel at the bottom of the reservoir, lifts it up and then puts it back down to work on the next layer. Because of that, one of the biggest challenges is making sure that your first few layers stick very strongly to the build plate. I’d say this has been my biggest challenge so far and I’ve had plenty of failed prints where it just hasn’t stuck and I’ve ended up with at layer of hardened resin stuck to the teflon at the bottom.

To achieve a good binding, there are two major factors that go into it. First, you simply expose the resin to the UV light for a lot longer on the first 5-10 layers. Typical expose time for a regular layer is 8-12 seconds. On the first layers you expose it for 40-80 seconds. This makes these first layers strong and well hardened and helps them bind to the build plate. The other part is to make sure that the build plate is as level as you can get it.

On the Photon, the build plate is connected to the mechanism that moves it up and down by a ball joint (that you can just see at the top of the picture above) which allows you to adjust the position of the plate. I’ve found that I need to realign this after every few prints. I think I’m applying too much force when trying to remove models from the plate, or not tightening the screw enough that holds it tight. I’m still working on making this more stable.

Layer Print Speed

Another difference is that it takes the same amount of time to print a layer whether there is only a small bit of the model on that layer or you’re filling the entire build plate. On an FDM printer, the nozzle has to travel over every bit of the layer where you want plastic to be laid down. Which means that the time spent on a layer depend on the amount of material to be placed. In fact, in the slicing software for FDM printers, there is an option you can set that is minimum layer time. This is because the plastic is still warm and if you print over the layers to quickly, you get smearing like you can see at the top of the corvette model in the earlier pictures.

On the SLA printer, it exposes the entire layer at once. Which means each layer takes exactly the same amount of time regardless of the amount of material being printed. However, because of the smaller layer sizes, you have to do more layers.

For single models, the FDM printer is faster. For example, the freighter print, and the frigates and sathar destroyer for that matter, all take about 4-5 hours on the Photon to print since they are all the same height and print time is just a function of the height of the model. The heavy cruiser took about 11 hours (I ran it overnight). On the FDM printer, those smaller models only took about 30 minutes to 1.5 hours depending on the layer height settings. So you’re getting the increased quality in exchange for increased time.

However, because the SLA printing is independent of the amount of material being printed, you can print a bunch of models all at once if they fit on the build plate. I printed the eight smaller ships (destroyer, 2 frigates, freighter, cutter, and 3 assault scouts) all at once. It took five hours and only filled about half the build plate area, if that (I could have packed them closer together). On the Rostock, that same set would have taken nearly 6 hours to print (at 0.1mm height resolution compared to the 0.05mm of the Photon) and the scaled down assault scout model would not have printed successfully at all as the details are too fine on that model. And that 11 hour print on the heavy cruiser? It takes 6.75 hours on the Rostock. And I can print 5 at a time on the Photon in that same 11 hours which would take just over a day on the Rostock. So while individual prints are slower, you can print many models at once and actually achieve a faster print speed with higher resolution. As long as it fits in the build volume.

Materials, Post-processing, and Clean-up

With the FDM printer, I just use PLA plastic which comes in 1kg spools that cost about US$22-25 depending on the color and transparent plastic costs a bit more. You can see one of the spools and its box in the very first picture sitting on top of the Rostock. For the SLA printer, you use a liquid resin that hardens when exposed to UV light at 405nm. You can buy it in 500ml and 1 liter bottles that cost about US$25 for the half liter bottles and US$40 for the liter bottles, again price varying slightly by the color and transparency. So the material on the SLA printer is a bit more expensive.

Additionally, you use more material for any given print. You always have to have a base plate (raft) that uses up material, plus the resin prints tend to be more solid than the FDM prints. There are techniques for reducing this that I’m still learning, but my resin prints are definitely heftier than the prints from the Rostock. Additionally there is a bit of resin lost in the clean-up process each time (although the amount is fairly small). All told, it probably costs about 2-3 times as much to print with the SLA printer than the Rostock.

There is also a bit more work involved on finishing a print with the SLA printer. With the FDM printer, once the print is done, you just have to let it cool, remove it from the build plate, remove the printing supports, and you’re done. Paint or use. It’s a bit more involved with the SLA printer.

First, the print is literally dripping wet. The last bit of just came out of the resin bath and you might have bits of liquid resin hiding in pockets higher up depending on the shape of your model. So you have to have to make sure that gets cleaned up.

Second, there is typically a thin film of uncured resin sticking to the surface all over the print. This needs to be rinsed off to get the highest surface detail. This is done by washing the material in a bath of high concentration rubbing alcohol (I use 91% isopropyl). The alcohol dilutes and washes away the uncured resin. This keeps it from binding to the model in the next step.

Finally, you need to finish the curing process. While the model is solid, it is not completely cured and you want to make sure it is. This can be accomplished in a number of ways. One is to buy a UV lamp that emits at 405nm and put the model under that for a while to finish curing at least the surface (which is really what you need, the interior will finish over time). The other option, which I typically use, is to take advantage of the big UV lamp in the sky and set the model out in the sun for 10-15 minutes. Of course that latter option only works during the day. At night I actually have a full spectrum lamp from an old fish tank that I use. It’s not super efficient as I don’t think it actually emits a lot of UV but it does work if I let it run overnight.

Since you’re working with a liquid, you get drops of resin falling across your work surfaces and printer as you’re working with the finished model, plus resin sticking to the tools you are using, so you have to make sure to clean it up as you go.

Finally, you have to deal with failed prints. On the FDM printer, you just pull the bad print off, make sure the nozzle is clean, and try again. There is a little more work with the SLA printer.

First, when a print fails, that usually means that it has come off the build plate and therefore is stuck to the bottom of the resin vat. Although I did have one failed print (of the heavy cruiser) where parts were just missing because they didn’t stick at first and then later layers worked. The printer comes with a plastic scraper for removing prints from the build plate and the resin vat when they get stuck there. However, you have to be very careful. The bottom of the resin vat is actually a thin sheet of clear teflon film. Clear so the UV light can get through, and teflon to help the resin not stick. This film has to be flat and intact for the printer to work. If you gouge it, it has to be replaced.

Which of course I did on the second day of printing. I was having a lot of failed prints and I accidentally caught the film with the corner of the scraper and gouged it pretty good making it no longer flat. Luckily the printer comes with two replacement films so I got to experience that right away. I haven’t had a problem since. (And I’ve ordered more film in case I do and for when the film just wears out from use.)

The other thing you have to deal with on failed prints, and even regularly after good ones, is little bits of cured resin in the vat. These have to be cleared out because if they get between the build plate and the bottom of the vat, the build plate doesn’t get into the correct position and the layer doesn’t cure properly which can cause it to not stick and the print to fail. This is done by removing the resin vat from the printer and pouring out the resin through through a very fine filter (that came with the printer) into a container. The little bits are removed from the resin and then you can replace the vat (after wiping it out) and refill it with the resin. The picture to the right shows the filter I’m currently using and all the little bits that have been filtered out. The filters that came with my printer are paper and eventually soak up a bunch of resin and have to be discarded. The printer came with 10 so I’ll eventually need to get some more.

Other Thoughts

Just a couple other thoughts before we wrap up. First is the smell. The PLA plastic that I use for the Rostock actually smells pretty nice. It’s not like air freshener nice but it is not a bad odor. The resin isn’t nearly as pleasant. And while it’s not too bad, you can definitely smell it when the printer is running. It’s best to run the printer in a well ventilated area. Also, there is a distinct odor from the rubbing alcohol as well. While I wouldn’t consider them to be really unpleasant, the extra odors from this printer are not as nice as the FDM printer. Of course, I’m not that sensitive to the smells so it might be worse for you.

Another topic is the slicing software that you use to make the print files. The printer comes with the software bundled on a USB stick and as far as it goes, the software works just fine. However, it is very limited in its functionality. It also has a bug in the rotation functionality that makes it a bit hard to position pieces if you want to rotate them. Namely, the x & y rotation work on the original model axes, no matter the model rotation, while the z rotation works on the printer z axis.

Additionally, it would be really nice if the slicing software would tell you how much resin was being used in a print. It gives estimated print times (which tend to be underestimates, I don’t think it takes the motion of the build plate into account) but doesn’t give you the volume of resin used. It also doesn’t do hollowing or drilling holes (an advanced topic I’m just getting to to reduce resin use) but that can be done in other software. I’ll admit that I haven’t checked the company’s website yet to see if there is a newer version of the software.

Others have recommend ChiTuBox which is what the bundled software is based on (an older version) as it does have all those features and fixes the rotation bug. But for some reason, I have yet to get a print to work using a file generated from that program. They always fall off the build plate despite having all the settings the same in the two programs (at least as much as I can. ChiTuBox has many more options). I’m still trying to figure that out. Right now I use ChiTuBox to position and hollow out the model and then use the bundled software to add supports and slice.

Finally, the touch screen is a little small. The icons and images are fine, but the print is really tiny. It’s a pretty high resolution screen crammed into a 2.7″ space so the words are small. I typically have to either use my magnifying glass lamp or put on reading glasses (even with my uncorrected closeup vision) to read the remaining time on a print.

Conclusions

The bottom line is that I really like this printer. Like any 3D printer, it has its quirks and there is a bit of a learning curve to get the best performance, but it is fairly turnkey and once I got the build plate leveling worked out, it pretty much just works. There is a bit more work involved in finishing the prints, and the materials cost a bit more, but it’s well worth it for the increased resolution.

I haven’t mentioned prices. My Rostock was a kit that I had to assemble and cost $900 (on sale from the regular $1000 price). The current model (the v4) is the same price as a kit and about $1400 assembled. You’re really paying for the large print volume with that printer. Getting a small FDM printer with a 6″x6″x6″ print volume will only cost you about $300-400 dollars. I got my AnyCubic Photon on sale for $300. The regular price is $539 but the sale price is still available (as I’m writing this) on Amazon. Here’s a link to the product page if you want to check it out.

So in summary:

Pros

- Low printer price

- Excellent resolution

- Can print multiple models in the same amount of time

- Easy to set up and use

Cons

- Slight smell

- Higher materials cost

- More post processing work

- Software somewhat limited and buggy

- Relatively small print volume

I’m really enjoying this printer and you can expect to see more prints from it in future posts. If you have any questions, comments, or suggestions, let me know in the comment area below.

You should also mention that you need to wear gloves so that you don’t get sensitized to the resin. Some people can become allergic to the resin after coming into contact with it once or twice.

I didn’t know about the allergy stuff but that’s a good point about wearing the gloves.